Types of stills for home-distillers

#KEEP IT SHINING with Moonshiners Tips from LIKKER TECH.

Types of stills for home-distillers

STILL TYPES

Stills for distillation can be broken down into two main categories, the basic Pot Still and the more complex Reflux Still

Let’s start with the most common still, the Pot Still.

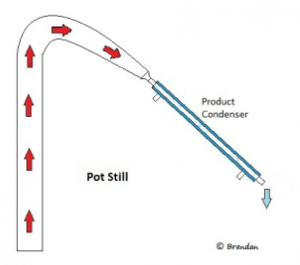

POT STILLS

A Pot still is named as a result of the simple way in how it operates. It consists of a boiler in where the wash is boiled to vapour temperature and has a simple column or collector on top of the boiler to allow the vapour to follow a path through the neck to the condenser.

With the heat source on the boiler the vapour will rise from the boiler and through the column where it reaches the neck at the top of the column (called the point of non-return) and then follows this path down into the condenser where the vapour is cooled and collected. All the vapour that passes past the neck of the column is condensed and collected assuming the condenser is adequately sized, be it in the form of a coil, Liebig or shot gun condenser. (I will discuss the types of cooling condensers in another topic)

The only way to control a pot still is by controlling the amount of heat you put into the boiler, whether power or gas is used as a heat source.

Most pot stills used by the home distiller are in the form of a beer keg with a short column on top of it or an Alembic still.

REFLUX STILLS

- Firstly, let's discuss the term Reflux: As Wikipedia describes it, Reflux is a technique involving the condensation of vapours and the return of this condensate to the system from which it originated. Reflux is thus gained in two behaviors namely by Controlled cooling or by natural means.

- Controlled cooling reflux: In simple terms, a reflux still has an additional condenser sitting usually on top of the column and by controlling the temperature of this condenser, often called a dephlegmator, a reflux still is used to ensure that higher boiling point components like water is returned to the boiler while lighter elements like alcohol is passed to the cooling condenser. This is useful in producing high quality alcohol, while ensuring that less desirable components (such as fusel alcohols, in other words “the bad stuff”) is returned to the boiler.

- Natural Reflux: By adding a copper "boiling ball" (also called a Whisky head or an onion head) in the vapour path creates an area where expansion of gasses into the ball causes cooling and subsequent condensation and reflux. Also, the addition of inert materials in the column (e.g., packing) creates surfaces for early condensation and leads to increased reflux. Packing generally used by the home distillers are either copper mesh, copper Raschig rings, ceramic packing or glass balls, and in some cases a combination of them.

Reflux stills are generally categorized to in 3 different types, this being LM, VM, & CM. These anagrams stand for Liquid Management, Vapour Management, and Cooling Management, and refer to the way in which the output condensation collection is managed. In plain words it’s the process used to control what, when, and how fast you collect from the vapour. There are many variations on these types, however for simplicity, I will only explain the basic operation of the three different types not to confuse the users with the combination and variations of them. Plated column reflux stills (bubble plates) is a type of cooling management still but this will be discussed in a separate blog together with still packing.

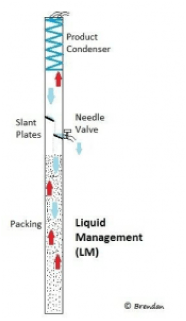

- LIQUID MANAGEMENT (LM)

The liquid management still controls the output of the actual liquid distillate which is allowed to exit the still to the cooling condenser. A typical LM still is the Bokakob (Boka or Bok for short) a common name for a Dual Slant-Plate Single Column In-line Reflux Still designed by Alex Bokakob in 2001. This still is popular with many novices for its simplicity to build and operate, while being able to yield 95% ABV neutral spirits by use of a needle valve.

The column contains two slant plates which are placed in on an angle in the vapour path of the column. As the vapour rises through the column, it reaches the reflux condenser on the top of the column, condenses into liquid and falls down the column. Some of this falling distillate catches on the top plate, which is slanted at a downward angle, and falls onto the bottom plate, which is angled upwards, and fills that space until it overflows and falls back down the column.

The output is controlled by a needle valve from the bottom plate and lets a small amount of the liquid to be drawn off. By keeping the valve closed for the first half hour or so of the distilling process, the column gets itself into a sort of equilibrium, where the continual rising of vapour and falling condensate, refreshes the liquid held by the slant plates and allows higher % ABV alcohols to be held on the plates.

As the needle valve controls the release of the liquid it is termed a Liquid Management still.

NOTE: For safety purposes the Bokakob still must have a free opening to atmosphere as not to place it under pressure during the equilibrium phase. Normally a small hole in the top end cap.

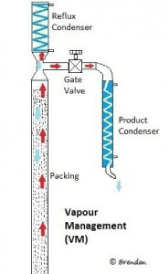

- VAPOUR MANAGEMENT (VM)

There are many various designs of the Vapour Managed still, just like the other categories, however a common design has a inline condenser at the top of the still and a tee-off branch below this condenser with a controlling valve to the cooling condenser to control the flow of vapour. A gate valve is normally used, although ball valves have been used, a gate valve gives much better control which is important in a vapour management column design.

The vapour rises in the column as normal, where the vapour path splits into two at the tee. Vapour that continues towards the top is condensed by the reflux condenser and falls back down the column as explained previously in the description of reflux. With the gate valve closed, the column continues in this cycle reaching an equilibrium where the alcohol components are separated in the column. Lighter alcohols find their way towards the top of the column, and heavier alcohols settle around the bottom of the column. The distiller would keep the valve closed for the first say half hour, to allow the column to separate the fractions of lighter and heavier alcohols. The valve is then slightly opened to allow a small amount of the vapour through it which will flow through to the cooling condenser for collection.

As the gate valve controls the release of the vapour, it is termed a Vapour Management style still.

NOTE: For safety purposes, as for the Liquid Management still above, the Vapour Management still must have a free opening to atmosphere as not to place it under pressure during the equilibrium phase. Normally a small hole in the top end cap.

This applies for both Vapour and Liquid Management stills, or any still where it is not vented to the atmosphere and can be closed off by a valve. You will not loose any alcohol if there is sufficient cooling in the reflux coil.

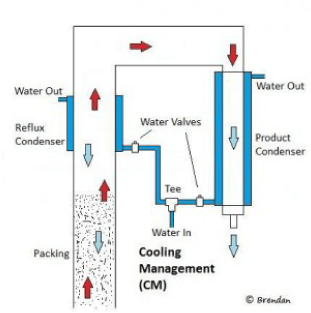

- COOING MANAGEMENT (CM)

The output of these column stills is controlled by manipulating the coolant water through the reflux condenser. The reflux condensers used in a cooling management still are usually inline and manufactured to allow the vapour to rise through it when the operator reduces the coolant flow to it. Typical designs of reflux condensers are water jacket and the shotgun condensers. Some designers have wrapped a coil on the outside of the reflux column, and this can also be considered as a reflux condenser.

The idea behind this design is that with sufficient cooling flow through the condenser the column can be held in full reflux so that all of the vapour is condensed in the column and falls back down the column as liquid. After the column has reached an equilibrium, the flow of coolant water to the reflux condenser can be restricted by control of a valve to allow a certain percentage of the rising vapour to rise through it and on to the product condenser where it is collected.

As the coolant water is manipulated to control the output from the still, it is termed to be a Cooling Management type still.

As mentioned above the plated columns (bubble plates) are also a type of Cooling Management columns as the cooling water is controlled to flood the bubble plates and to allow the amount of vapour to rise towards the collection condenser. I will discuss the plated columns in another blog together with column packing as the bubble plates are basically packing.