Sugar Wash Recipe

#KEEP IT SHINING with Moonshiners Tips from LIKKER TECH.

Sugar Wash

Recipe

-

City skyline

Photo By: John DoeDownload Sugar Wash Recipe

Sugar Wash Recipe.

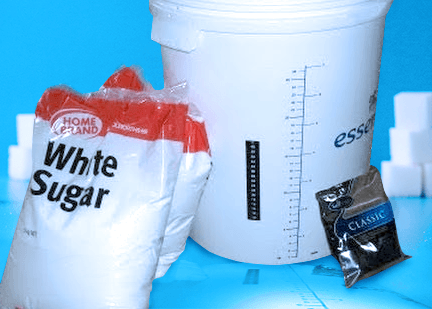

Base Ingredients & Materials

- 21 Litres of Distilled Water (You can use tap water if clean)

- 5,5kg of Raw Cane Sugar (Normal white sugar works best)

- 40g Turbo Yeast

- Brew Pot or Urn

- Floating Thermometer

- Long Spoon

Before you start the sugar wash procedure, be sure to thoroughly clean and sanitize all of your distilling equipment.

Making the Sugar Wash

- After sanitizing, your brew pot, place it on a heat source and pour in 17 litres of water.

- Heat the water to 50 °C.

- Dump the hot water into your fermentation bucket.

- Stir in Raw Cane Sugar and stir with your long spoon until the sugar is completely dissolved. (you may have to stir for a while to get the sugar to fully dissolve into the water)

- Once the sugar is fully dissolved, pour in 4 litres of cold water to bring the temperature of the wash down.

- Check temperature and stir your wash for 30 seconds every 5 minutes until the temperature cools to 28 °C. (This process can take several hours on its own but can be sped up significantly with the use of an immersion cooler.)

- When the wash has cooled to 28 °C, add the turbo yeast into your mix.

- Aerate the wash by dumping it back and forth between two separate containers for 5 minutes. You can also stir like crazy to aerate the wash.

- Pour the wash into your fermentation bucket. It is important to have the bucket seal properly and an airlock.

- Seal your fermentation bucket with the airlock and store in a dry and dark place around 24 °C – 28 °C.

Fermentation

A wash made purely with raw cane sugar will need to ferment for 3-7 days and when ready, should no longer taste sweet or emit gas from the airlock. The yeast will fully convert all the added sugars to alcohol in the wash during this time period. You’ll know that the fermentation is complete when there is no gas coming out of the airlock in your bucket kit.

After 3-7 days, open your fermentation bucket and stir in the clearing agent. A clearing agent is used to clear the wash of any leftover yeast cells or unwanted solids. Within 24 hours over 90% of these unwanted compounds are pulled to the bottom of the wash. Note, that if yeast cells are not removed, they will break open during boiling, releasing off-flavors and aromas into the distillation process and reducing distillate quality. It usually takes less than 24hrs to completely clear the fermentation.

Straining

Once fermentation is completed and the added clearing agent has finished, we’ll need to leave behind any solid material that is leftover. The unwanted solid materials can lead to headaches if left in the wash and distilled. A cheesecloth is a great option for straining the wash before distillation. You can also use an easy siphon for transferring all the usable wash, while leaving the unwanted sediment behind to be disposed of.

(Advanced) Some distillers will test the pH of their wash. The ideal pH is 4.5 to 5.0. Use citric acid to bring the pH down and calcium carbonate to bring it up.