What types of condensers are used in the craft distilling?

#KEEP IT SHINING with Moonshiners Tips from LIKKER TECH.

What is a condenser?

A condenser is an apparatus that cools vapour or steam thus converting the vapour to its liquid form. During distillation of alcohol, alcohol vaporises at a lower temperature than water, this vapor travels to the condenser and then the condenser helps change the vapor to liquid alcohol. Thus, the alcohol vapour that travels through the line arm towards the cooling condenser is then cooled and returned to a liquid form. The condenser is the most important part of the distilling process because it controls the internal re-distillation process and the separation of the final output. Depending on the type of still design, the condenser may be located at different positions to provide different functionality in the still operations.

Types of condensers

There are basically five types of condensers used in the craft distilling industry which I will explain below. The larger manufacturers use more modern plate condensers but these are seldom used by the craft/home distillers and will not go into their design and use.

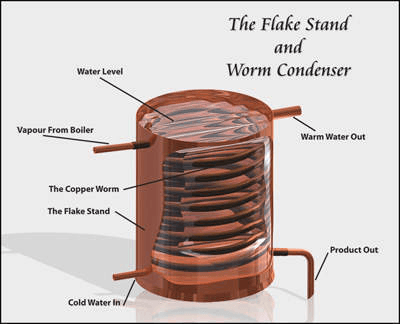

- CONDENCER COIL

This is the simplest format of a condenser. Ever seen moonshiners on TV or some pictures of the old moonshiners? Using a drum filled with cooling water a copper tube is spiraled in the drum on a downwards slope to allow the vapour from the line arm to flow down the coil and with the water in the drum to cool the condensate to a liquid form. This may not be the most effective way to cool your distillation as many times the user needs to replace the water or constantly replenish it to keep it cold enough for the distillation to return to liquid. One of the reasons the old moonshiners always set up their stills near a water stream and the modern shiners next to the swimming pool…

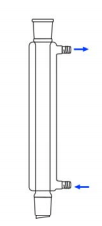

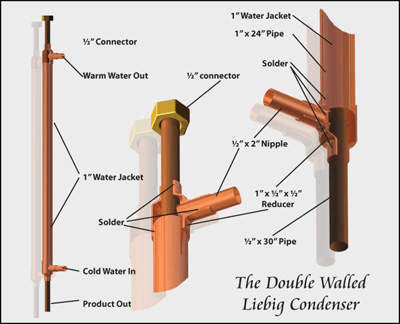

- LIEBIG CONDENSER

A Liebig condenser has an inner tube going straight through a surrounding tube with a water inlet and a water outlet in the outer tube. The outer tube works as a jacket of water and the flow of water through the jacket condenses the alcohol vapor in the inner tube. This is a very efficient condenser. It is used in both pot and reflux still designs. The Liebig condenser is a simple yet very effective condenser for the home distiller to make and use.

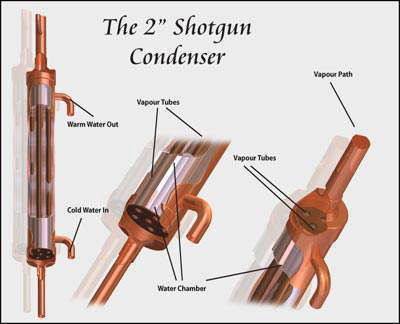

- SHOTGUN CONDENSER

Although similar in design and functionality to a Liebig condenser the shotgun condenser differs only that it has multiple inner tubes instead of just one. The water jacket concept is still the same where the cooling water supply runs between the jacket and the core tubes. This condenses the liquids contained in the hot vapours coming from the column and going through the core.

These condensers (also called Dephlegmators) is also used on the top of a packed column in order to divert some of the condensed alcohol out of a collection tube, while the rest is dripped back down over the packing. Many users use a shot gun condenser for their final cooling condenser.

Shotgun type condensers have become favored among many distillers of Scotch because they cause the final spirit to have a higher copper content. The higher copper content causes the final product to be smoother and less sulfured.

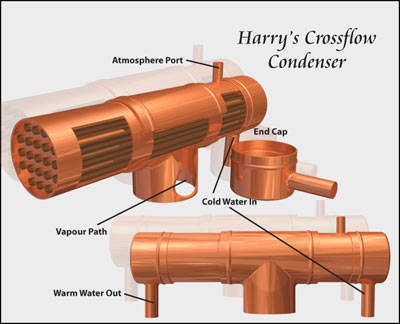

- CROSSFLOW CONDENSER

In design, it is the reverse of the so-called "shotgun" condenser in that the coolant flows through the tubes and the vapour passes over the tubes at right angles, allowing much larger volumes of vapour to be condensed for no increase in condenser size.

The Crossflow condenser is a concept used extensively in large-scale steam recovery systems for turbines. Applied to ethanol distilling, it is particularly suitable for coolant recirculating (recycling). Its advantages over other condensers are very low coolant friction, therefore low-power pumping requirements; compact size compared to product volume output; Large heat transfer surface. Very few of these are used by the craft/home distillers due to the difficulty in build and keeping the tubes clean.

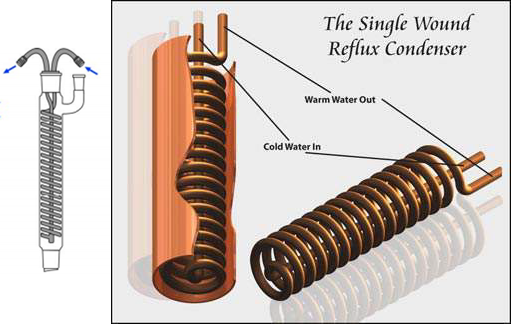

- HELIX COIL CONDENSER

Helix coils are a metal tube that has been bent into a spiral shape. Depending upon the required specifications of the finished product, a helical coil may consist of only one or two spiral turns or may be a series of spirals several feet in length.

Cooling water is circulated through the tubing which causes vapor to collect on the outside and normally used in the top of a reflux (Bokakob) still. The advantages of this type of this condenser is that you get a lot of cooling power into a small volume.

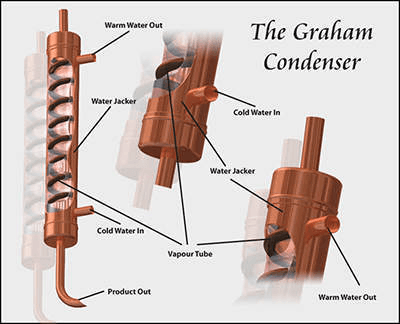

A Graham type of condenser is the reverse of a Coil Condenser where the vapour flows through the central tube (Coil) and condenses along its walls to flow towards the collection point and the cooling water on the outer of the coil. Basically a Liebig but the inner tube is not straight but coiled.